Team Members: Doruk Senkal, Mohammad H. Asadian

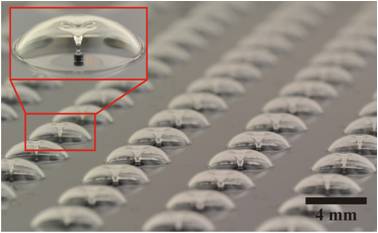

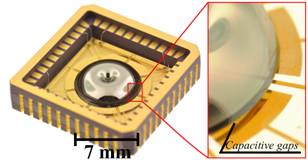

Toward the realization of a high performance, 3-D micro-machined rate integrating gyroscope, the University of California, Irvine is developing a new paradigm for wafer-level fabrication of inherently symmetric, atomically smooth, high Q-factor gyroscopes. The approach, pioneered by UCIrvine, uses surface tension and pressure driven micro-glassblowing process to form arrays of miniature high aspect ratio hemispherical shells with self-aligned stem structures. The current program focuses on improvements in as-fabricated frequency symmetry and maximization of the Q-factor by using low internal loss materials such as fused silica and Ultra Low Expansion Titania Silicate Glass (ULE TSG).

Rate integrating gyroscope offers a number of unique advantages for DoD applications: high dynamic range, low noise due to degenerate mode operation, high accuracy due to direct measurement of the angle of rotation, and ability to operate interchangeably in the whole angle and angular rate modes. These advantages, combined with reduced C-SWaP due to miniaturization, offer a significant potential in enabling a number of DoD applications, including an inertial navigation system for deployment on spin-stabilized missiles, pointing technology for high-g munitions, and azimuth-based target mapping.